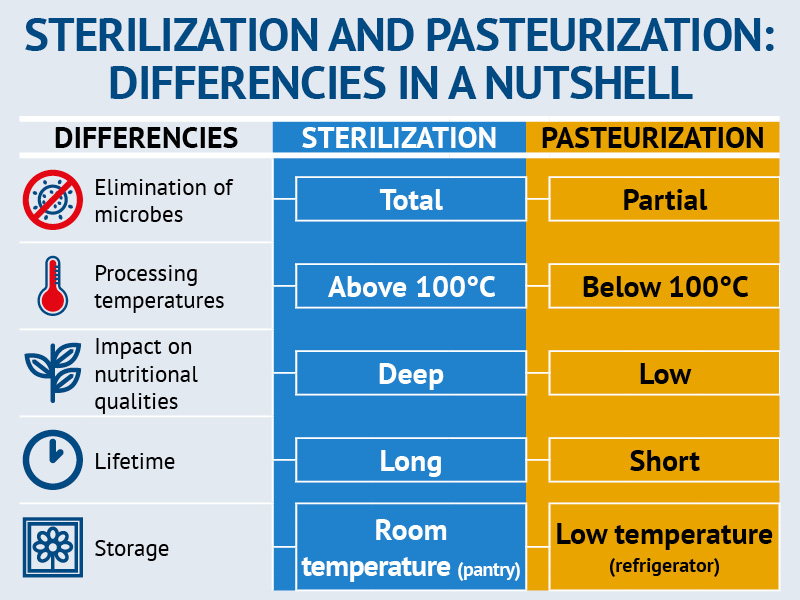

Outside the small circle of professionals, there is a great deal of confusion about what pasteurization and sterilization are and what differentiates the two systems. Pasteurization and sterilization consist in heating a food to break down its bacterial load. Sterilization almost completely eliminates the bacterial load, while pasteurization only reduces it.

When is one procedure used and when the other? Is it better to pasteurize or sterilize? Read on and you will find all the answers!

The mistery of food preservation

Nowadays all kinds of food products populate our refrigerators and pantries at any time of the year. But until a few years ago the situation was profoundly different. For centuries food storage was an enigma. Various tricks were invented to preserve meats, fruits, vegetables and other foods, but they were empirical systems, based on direct experience, and they did not always give the desired results.

Why food degraded was an enigma until the 19th century when the secret was finally revealed.

The French chemist Louis Pasteur, after years of research and experiments, made 3 very important discoveries:

- Microorganisms are the main cause of food degradation.

- High temperatures kill microorganisms.

- Microorganisms always arise from other microorganisms.

These principles found their practical implication:

- Foods exposed to a source of intense heat contain fewer microorganisms.

- With fewer microorganisms, food conservation lasts much longer, and the food is safer.

- Microorganisms can no longer form if they are completely eliminated from a food.

From these discoveries derive the current sterilization and pasteurization processes.

Sterilization

This is the most drastic process, which aims to completely eliminate bacteria by exposing food to heat above 100 ° C.

This temperature, higher than the boiling point of water, is lethal for the vast majority of living beings. Consequently, it is sufficient to eliminate almost all of the bacterial load of a product.

After sterilization, foods are almost completely free of bacteria, and as a result they can last for years at the storage temperature and conditions indicated by the manufacturer.

The downside is that many flavors and nutrients contained in food are thermolabile. This means that they cannot stand the heat and therefore they deteriorate. As a result, sterilized foods can change their taste and be less nutritious than fresh products.

In sterilization, a particular value of F, F0 is defined, which is the duration of the sterilization process at 121.11 ° C (or 250 ° F).

What are the sterilized food products?

On the shelves of a supermarket, you can find a whole range of long-life foods, including:

- Jams

- Preserves

- Canned tuna

- Tomato puree

- Canned legumes

Pasteurization

This process consists in exposing food to heat usually below 100 ° C. At these temperatures the bacterial flora is destroyed but not completely eliminated. In addition, the food does not completely lose its taste quality and keeps its nutritional properties intact.

The pasteurization process, in turn, is divided into:

- Low pasteurization : the food is exposed to temperatures of 60-75 ° C for an extended time (for example 30 minutes).

- High pasteurization : the food is exposed to temperatures of 75-100 ° C for a shorter time.

Pasteurization is calculated in PU (Pasteurisation Units). One pasteurization unit is defined as 1 minute of product exposure at 60 ° C.

Obviously, since the bacterial flora is still present, the shelf life of pasteurized products is relatively limited. However, the storage time is still longer than the fresh product.

Pasteurization is often used not only to improve conservation, but to eliminate some types of bacteria that are dangerous to health and therefore make the product safer. This is the case with milk and eggs, which are pasteurized to eliminate heat-sensitive enzymes and pathogens.

As for foods rich in sugars, such as honey or beer, pasteurization aims to break down the bacteria responsible for fermentation.

Unlike sterilized products, which can be stored at temperatures similar to room temperatures, many pasteurized products keep best at low temperatures, such as those in the refrigerator. In this way the excessive development of the bacterial flora still present is avoided.

What are the pasteurized products?

The foods that are pasteurized are:

- Milk

- Fresh cheeses

- Cream

- Beer

- Bases of ice cream

- Eggs

- Preserves

- Honey

- Fresh pasta

As you can see, pasteurization is also used for solid foods. Furthermore, not all of them should be kept in the fridge.

Pasteurization temperature monitoring with data logger: a real case

Industry: Food and beverages

Company Size: family company sice 1975

Location: Italy, Piemonte

The company is located in an area famous for the quality of the truffles that grow there. The company is in its second generation and for years has been awarded the title "Artisan Excellence", released by the Piedmont Region in recognition of its thirty years of experience in the world of gastronomic craftsmanship quality. The company carries on the prestigious family tradition with enthusiasm and new ideas.

The customer's request

The customer needed to find a small data logger to insert inside the truffle preserves during the pasteurization process. As we know, the valuable product is usually packaged in very small jars.

Study and analysis

It was crucial to know the height of the lowest and highest glass jars. The product had to be placed in a very small jar. Therefore we chose the S-Micro, the lowest volume data logger for high temperatures available on the market, equipped with a customizable length probe.

Moreover, thanks to the use of the fixing base equipped with pivots of different heights, the same logger can also be used to monitor jars of other sizes.

Application

The customer, not knowing this type of instrumentation, requested a demonstration on the field. A member of our team made an appointment and then went to the customer site for a demo.

Solution

During testing, the data logger proposed in combination with our accessories proved to be suitable for monitoring the pasteurization process.

The customer was thrilled. The availability of such a small logger together with Tecnosoft's flexibility to customize its solutions according to customer needs, in this case with the tailor-made probe, proved to be the winning solution.

Do you have a similar need to solve? Ask us for information today

Flip through our history

Flip through our history